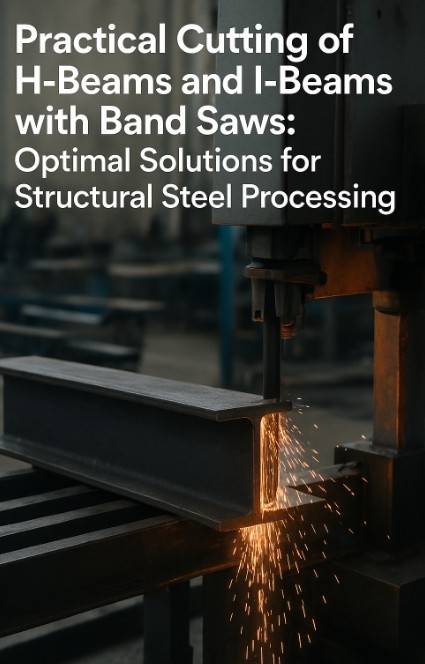

Practical Cutting of H-Beams and I-Beams with Band Saws - Optimal Solutions for Structural Steel Processing

Structural steel remains one of the most critical materials for modern infrastructure, from high-rise buildings to long-span bridges. Among the most commonly used sections, H-beams and I-beams form the backbone of load-bearing frameworks. Processing these beams with precision is essential to ensure safety, efficiency, and long-term durability in construction projects.

Large band saw machines from Everising Machine Co. provide reliable solutions for these challenges, enabling precise, safe, and efficient cutting for both construction and bridge applications.

Understanding H-Beams and I-Beams

Although H-beams and I-beams appear similar, their structural differences determine both their engineering performance and cutting requirements.

| Feature | H-Beam | I-Beam |

|---|---|---|

| Flange Width | Wide and thick | Narrower and thinner |

| Web Thickness | Generally thicker | Generally thinner |

| Strength | Higher load-bearing capacity | Lighter, suitable for medium loads |

| Common Applications | Bridges, columns, heavy-duty structures | Multi-story buildings, floor and roof frameworks |

| Cutting Implication | Requires robust, stable cutting power | Faster to cut but needs precise alignment |

Cutting Challenges in Structural Steel

Processing H- and I-beams presents multiple challenges:

- Large cross-sections demand stable power and blade engagement.

- Heat management is critical to maintain structural integrity.

- Heavy beams require proper clamping and material handling systems.

- High-volume production requires consistent repeatability and automation.

Traditional cutting methods, including flame or abrasive cutting, generate excessive heat and rough edges. Band saw machines overcome these limitations by delivering cool, precise, and repeatable cuts.

Advantages of Large Band Saws for Structural Steel

Large horizontal band saw machines are particularly suited for structural steel processing due to:

- High cutting precision and smooth surfaces.

- Reduced heat impact on steel properties.

- Flexibility for miter and bevel cuts.

- Integrated handling systems for safety and efficiency.

- CNC controls for repeatable and high-volume production.

Applications in Buildings and Bridges

Structural beams are indispensable in two major sectors:

- Bridges – H-beams serve as primary girders, where clean, straight cuts are essential for welding and splicing during assembly.

- Buildings – I-beams are widely used in floor and roof structures, where precise cuts accelerate installation and minimize on-site adjustments.

Industry Trends in Structural Steel Processing

The global demand for structural steel continues to rise, driven by urbanization and infrastructure expansion. According to Allied Market Research, the structural steel market is expected to surpass $225 billion by 2031, growing at a CAGR of over 5%.

Key trends impacting beam cutting include:

- Adoption of CNC automation for higher efficiency.

- Sustainable construction practices prioritizing recyclable materials (World Steel Association).

- Growth in bridge and transport infrastructure, increasing demand for H-beams (Global Construction Review).

Conclusion

H-beams and I-beams are fundamental to modern construction and bridge engineering. Their distinct geometries present specific challenges in processing, but large band saw machines provide the optimal solution by combining accuracy, flexibility, and safety. As infrastructure projects expand globally, reliable band saw technology remains a cornerstone of efficient and precise structural steel fabrication.